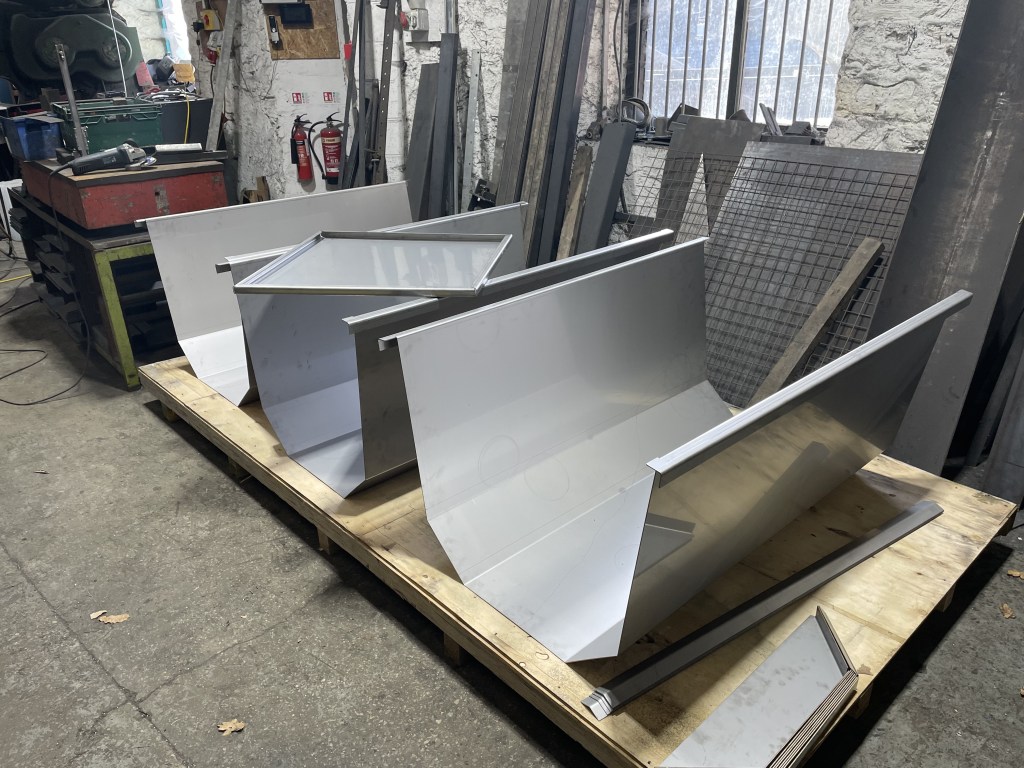

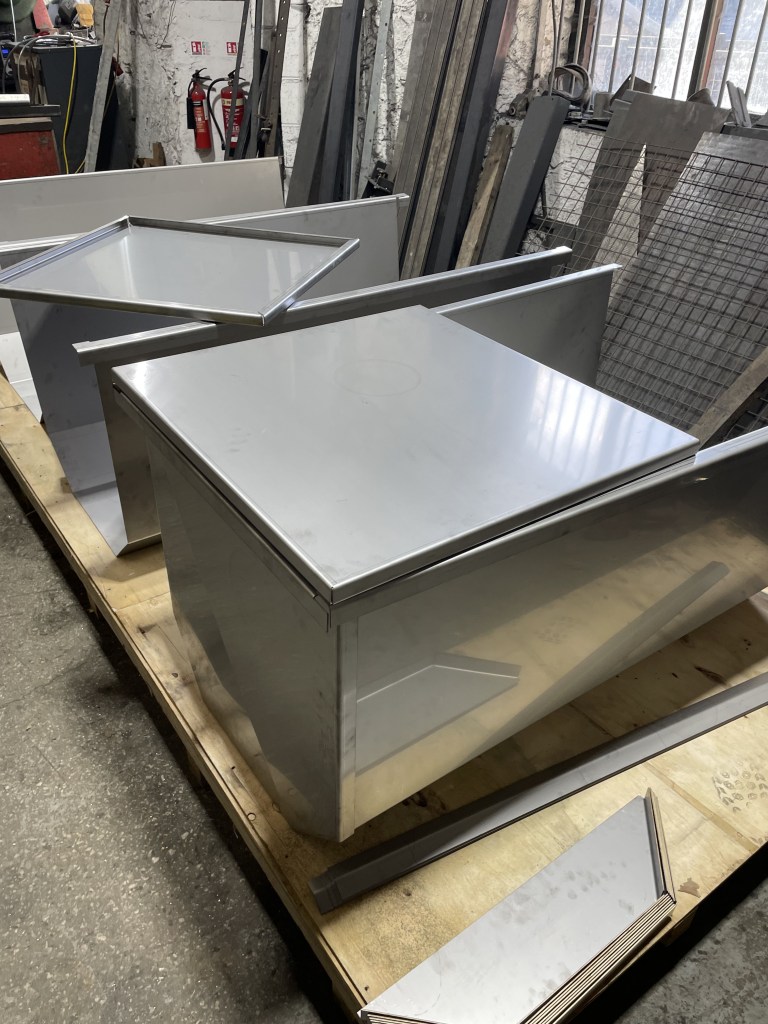

I was commissioned to design a dip tank for stripping alloy wheels of their powdercoat, using an existing tank as a reference point. This tank was to be made using 2mm stainless steel – laser cut and folded on a press brake – then TIG welded all round, double seamed. Not one to get wrong!

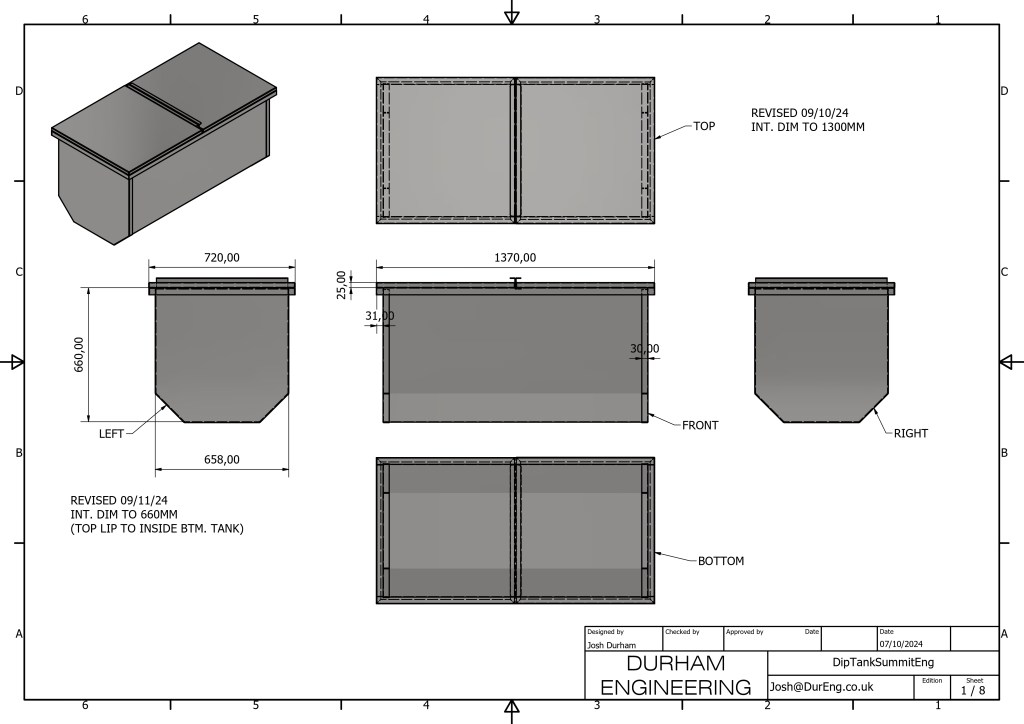

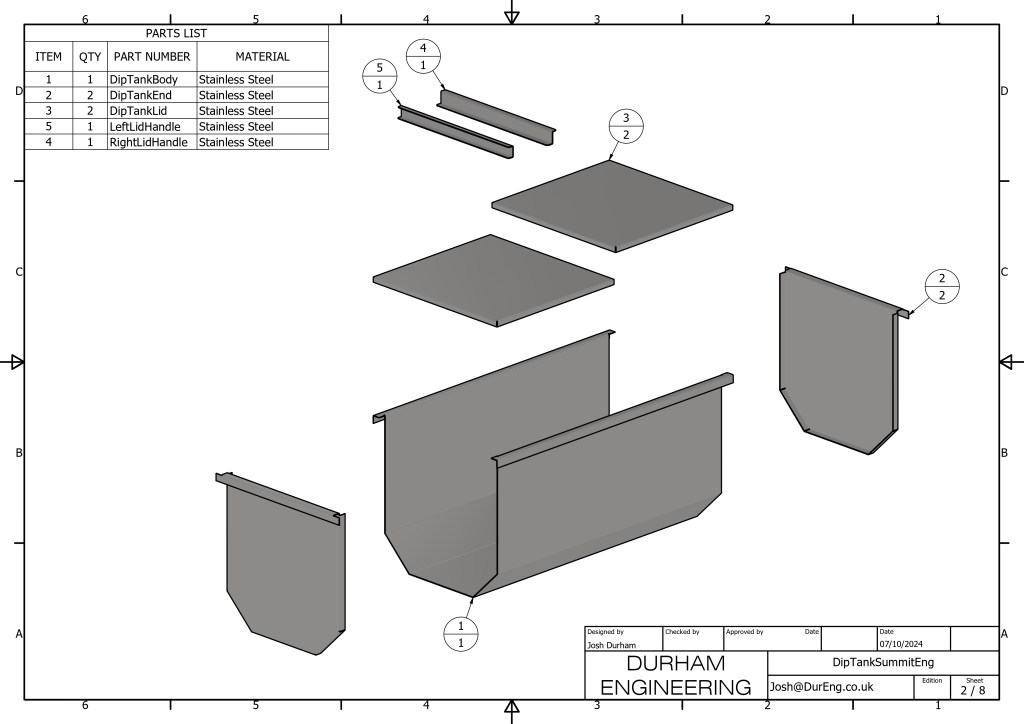

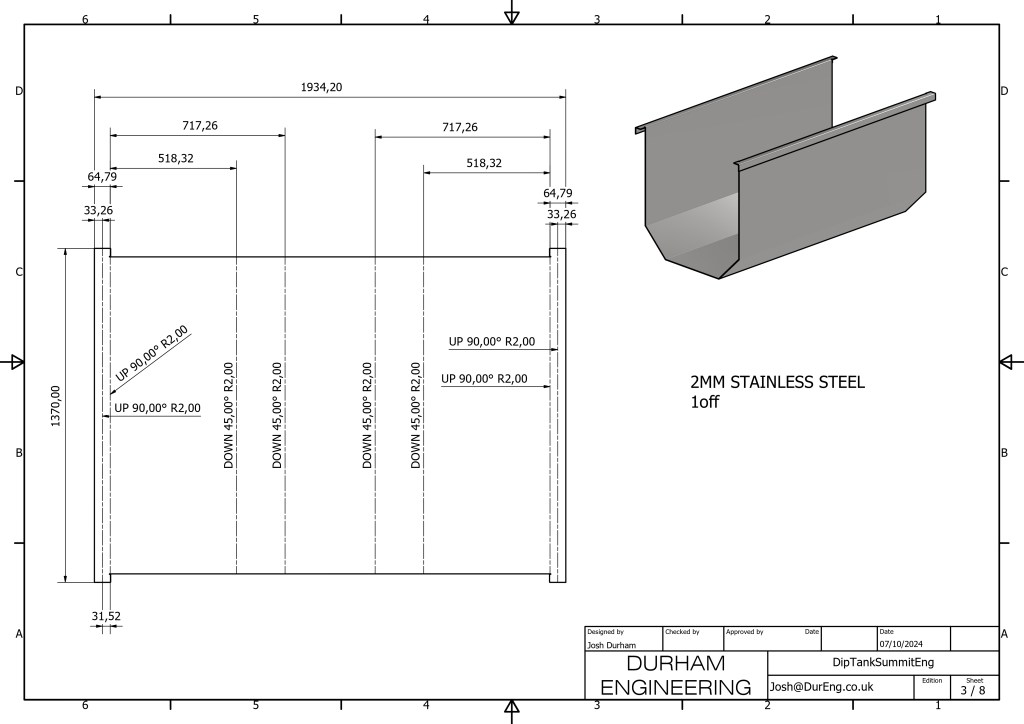

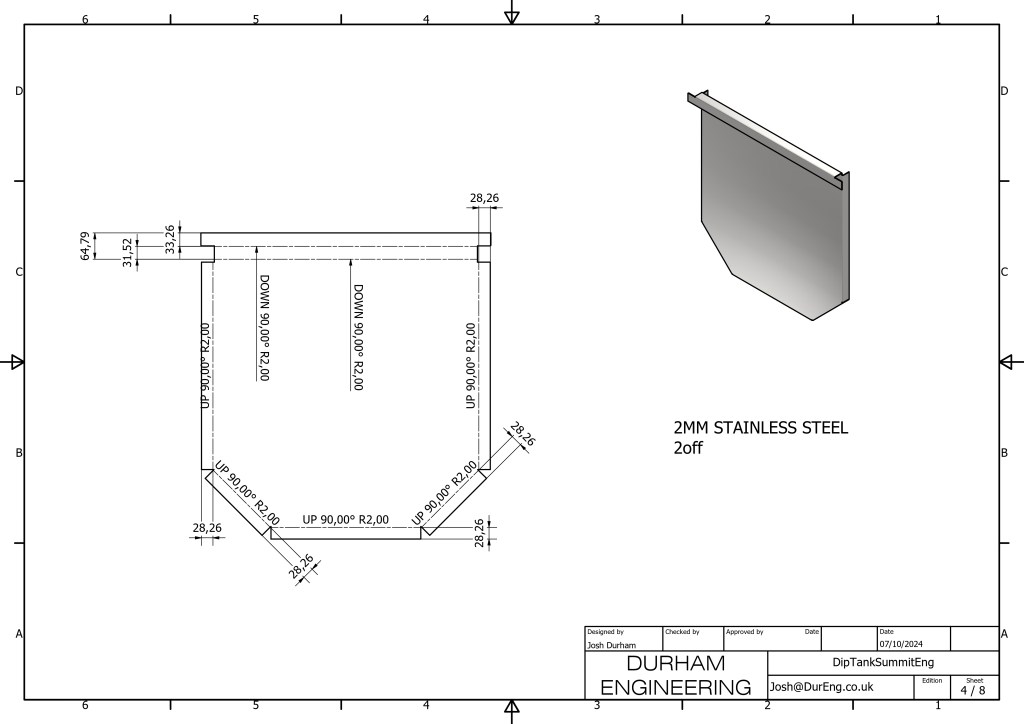

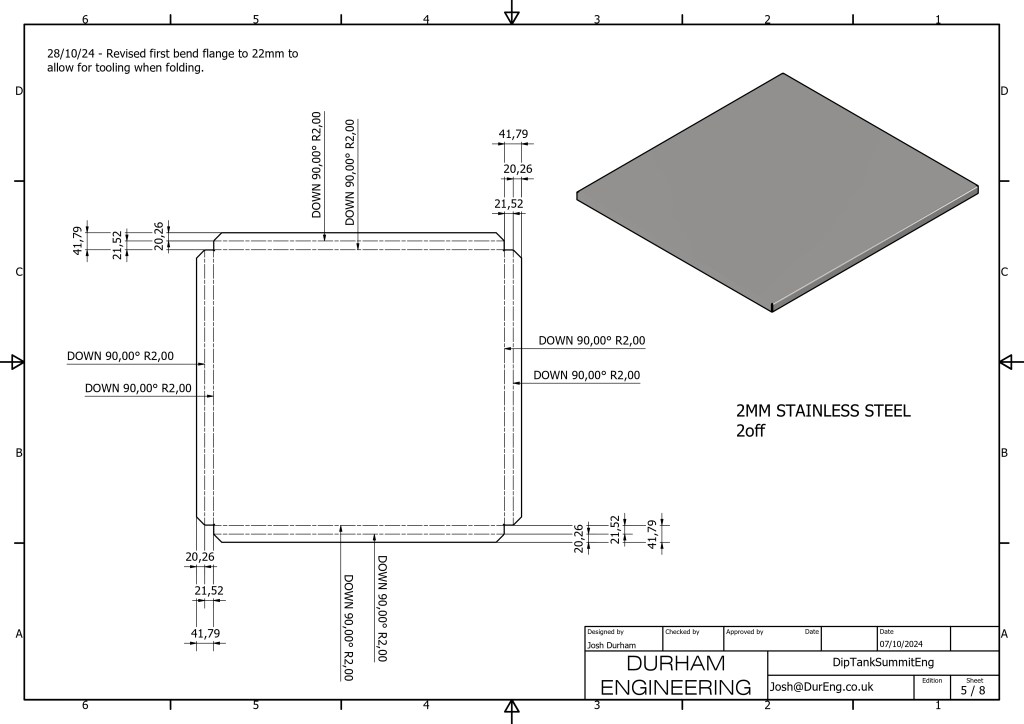

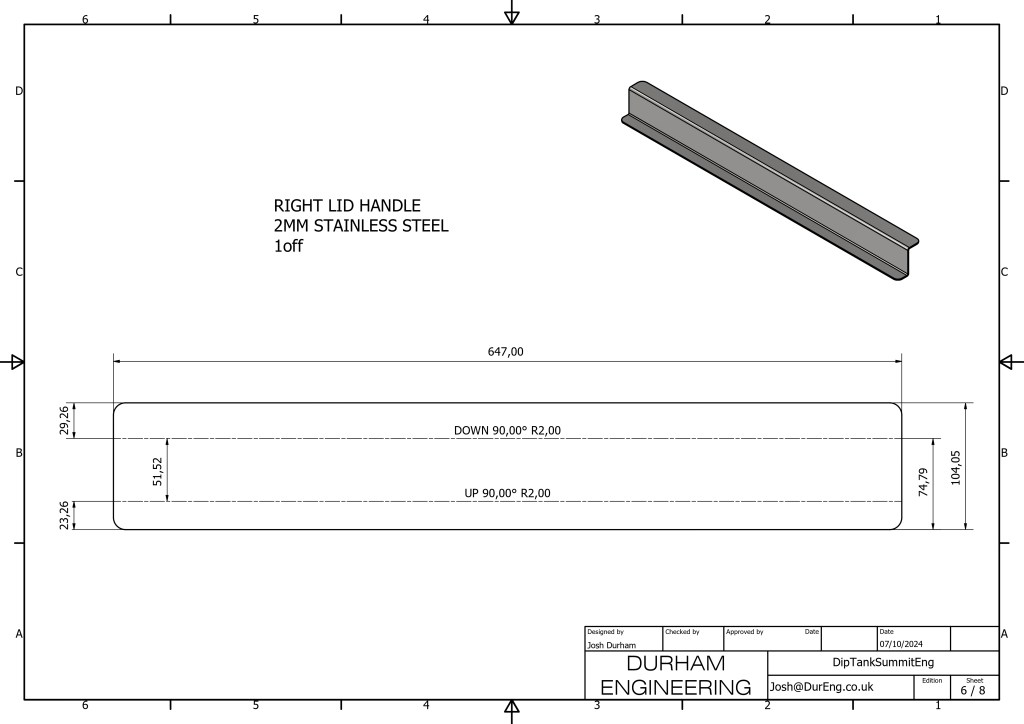

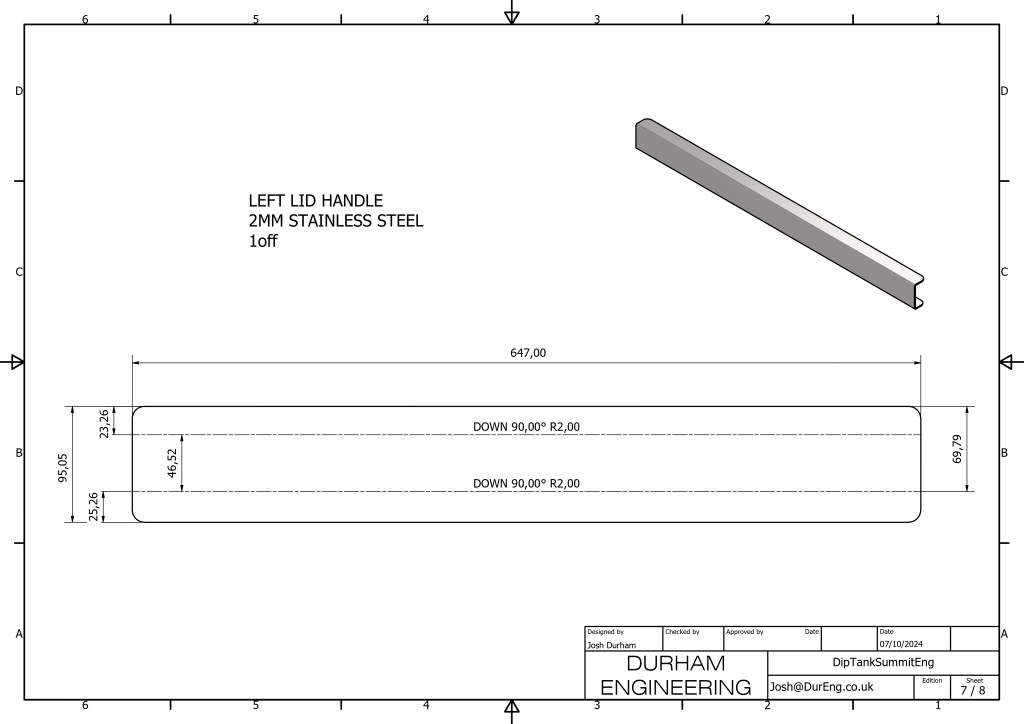

Below are the drawings I supplied to the client, with fold instructions and separate DXFs for ease of programming on the laser. The fold drawings are designed with available tooling in mind.

The first two pictures below are of the tank that was provided as a reference by the client, the remaining pictures are the cut and folded parts done to my designs and drawings. The final picture is the welded assembly, sitting on a stainless SHS frame.

This was quite a challenge, working with pretty expensive material and tight tolerances to match existing parts. The client was happy with the end result and I think a run of 5 were made initially. I enjoy working with sheet metal, if you have any sheet metal work that needs completing please send me an email at josh@dureng.co.uk.